Expand your product line up during Fall, Winter, and Spring.

As temperatures drop after summer, demand shifts in the apparel decorating industry from tees to jackets, vests and hoodies. While this can bring bigger margins, it also brings bigger challenges.

Summer apparel is largely cotton or polycotton, which makes decorating straightforward. But in fall, the most popular garments often feature technical fabrics like tech fleece, which pose issues for decorators.

Heat sensitive fabrics - The enemy of productivity for professional decorators.

Whether you’re screen printing or heat pressing transfers, too much heat can ruin sensitive garments. For screen printers, it’s not as simple as turning down the temperature on a dryer and getting to work. Dryers can take an hour to cool down – send your jackets down the tunnel too soon and they’ll come out a size or two smaller or melt trims, buttons and zippers. Cooling down takes time. And time is money. Especially when you need to be drying cotton garments at the same time – you can’t do both.

When heat pressing, if your heat press is still set at 320° (a typical heat for cotton garments), you risk scorching technical fabrics, leaving visible burn marks. Not good on a jacket that could cost over $100. But turn down the heat, and most heat transfers won’t stick or peel properly, and could come off when washed.

So, what’s a print shop to do?

Supacolor developed a heat transfer specifically for these situations, the LoMelt heat transfer. It uses our own low cure adhesive, which bonds strongly at just 260-270° in just 10-12 seconds. Depending on your fabric, you can use a hot, warm or cold peel.

You can use it to decorate heat-sensitive gear like high poly count blends, tech fibers and PVC-coated bags.

If you think your fabric may show dye migration even at a lower temperature, we also have a Lo Melt Blocker heat transfer. With the blocker, you’re guaranteed to have no bleed and no stress. The only thing it can’t be used on is waterproof coatings (but water-resistant coatings are fine).

Push the limits of what you can decorate.

Because of its low cure adhesive, you may be surprised by what you can decorate with the Lo Melt heat transfer. Experiment on garments and bags, even ones coated ones – it's all about testing through trial by fire (or better yet, heat press).

Share your results with us! We'd love to hear about what you were able to decorate with this incredible product. To get you motivated, watch how our #Supafam Big Brandoh used Lo Melt to decorate these mesh safety vests:

Turn down the heat, ramp up production.

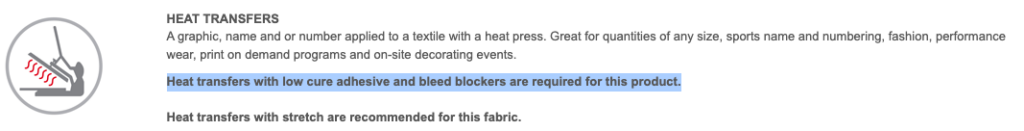

In fall and winter, don’t miss out on the extra revenue you could make from expanding your apparel decorating options. If the garments you want specify a low cure adhesive (see image below), remember the Lo Melt transfers from Supacolor. With them in your toolkit, we’ll help you make it.

If your apparel specifies this, you need to use our Lo Melt heat transfers.