Incorporating a heat-pressing department into your screen-printing business can change the way you think about your operations. Taking on low minimum jobs and high color counts can evolve from being an inconvenience to a great way to increase your revenue. But where do you get started? Don't worry; we're here to help.

Whether you're adding a heat-pressing department to your large-scale venture or looking to start a business from the comfort of your home, there are tools for every budget and every garment decorator. With the right equipment, you'll be well on your way to increasing your business's bottom line.

Manual heat presses have basic, yet essential, features that require the operator to use physical force to open and close them. Manual presses have limited functionality, but they are a great way to get in the game because they are available at a lower-cost entry point. When buying a manual heat press, look for one that has an auto-open feature, as this will eliminate some of the necessary physicality.

Utilizing optional platens helps to solve the problem of printing on awkward items. You can swap out platens for different jobs, such as garments with zippers & buttons, as well as shoes or bags. This will make heat pressing different items a much easier process.

Specialty presses are available for pressing headwear, neck labels, bags, shoes, and other items. Specialty presses can help you further build your decorating business by giving your shop enhanced customization capabilities. Don’t be limited to just printing t-shirts; you can charge an even higher premium for printing unique items.

Air-operated presses run off compressed air and do all the heavy lifting. These presses feature programmable settings that your machine will be able to memorize. With the click of a few buttons, the press platen will drop, apply consistent pressure and heat, then rise when the dwell time has been completed. Air-operated heat presses help avoid operator fatigue and repetitive injuries that can be caused by manual heat presses. They allow your employee to maintain focus for longer and achieve greater productivity. Air-operated heat presses come in single station, dual station, and multi-head station setups. The more stations, the more volume produced.

A temperature gun uses an infrared beam to detect any discrepancies in temperature on different areas of your heat press. Cold spots on your platen may cause inconsistencies in your print quality, so it’s important to ensure the temperature is evenly distributed.

If you’re just starting out, or if you need to secure your transfer onto an awkward shape, heat tape will keep things locked in the position you desire. Eliminate mistakes caused by shifting transfers by using tape specifically designed to withstand extreme temperatures.

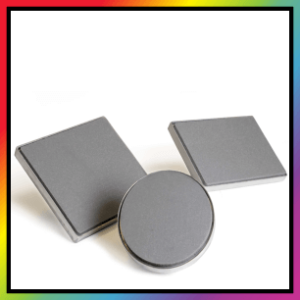

These special pads can be positioned on the bottom platen of your press and will act as the surface for your garment. These are useful when dealing with bulkier items as they help distribute the pressure more evenly.

Heat Transfer Warehouse, Pro World, and Heat Press Nation all are reputable vendors that sell a variety of heat pressing equipment and accessories. Good luck with your heat pressing venture, and let us know how else we can help you make it. Email us at hello@supacolor.com